Has an area of 100 x 50 M above the land using the best Paving Blocks, so that the conditions of the containers are kept safe.

Able to accommodate 60 Containers with 2 Tius stacking.

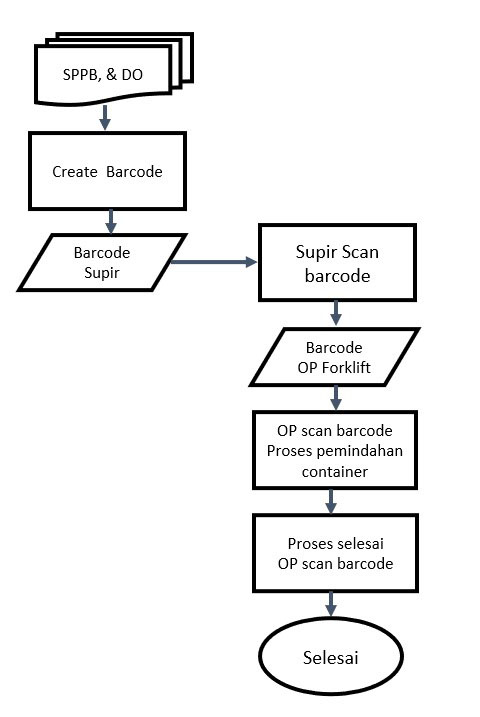

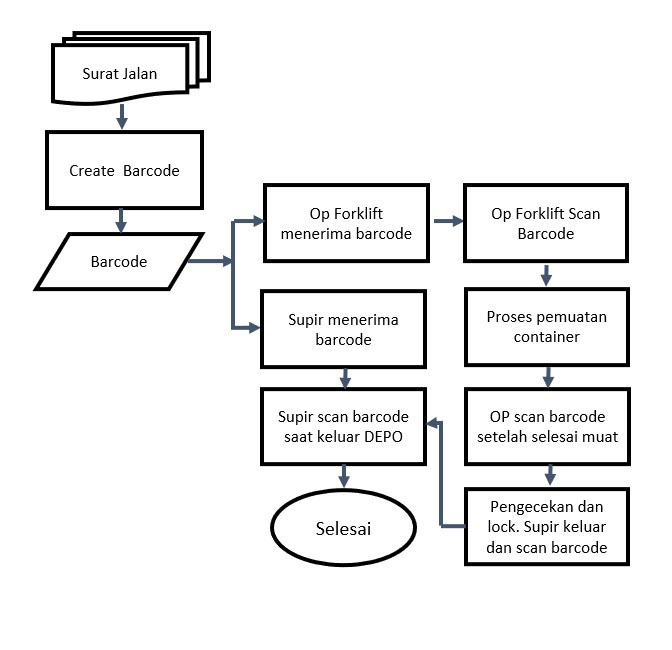

The depo is operated with a WEB-based application system and is supported by a scan box that is automatically updated on the system so that the in and out container reports are properly recorded.

Has guaranteed security, location within the Marunda Center warehousing and industrial area, wall fence surrounded by razor wire, 24-hour security guard also surrounded by CCTV surveillance.

Has guaranteed security, location within the Marunda Center warehousing and industrial area, wall fence surrounded by razor wire, 24-hour security guard also surrounded by CCTV surveillance.

Has a fast work process, because DEPO was specifically established and not for the public.

Serving 24 Hours.